20

Jan

Jan

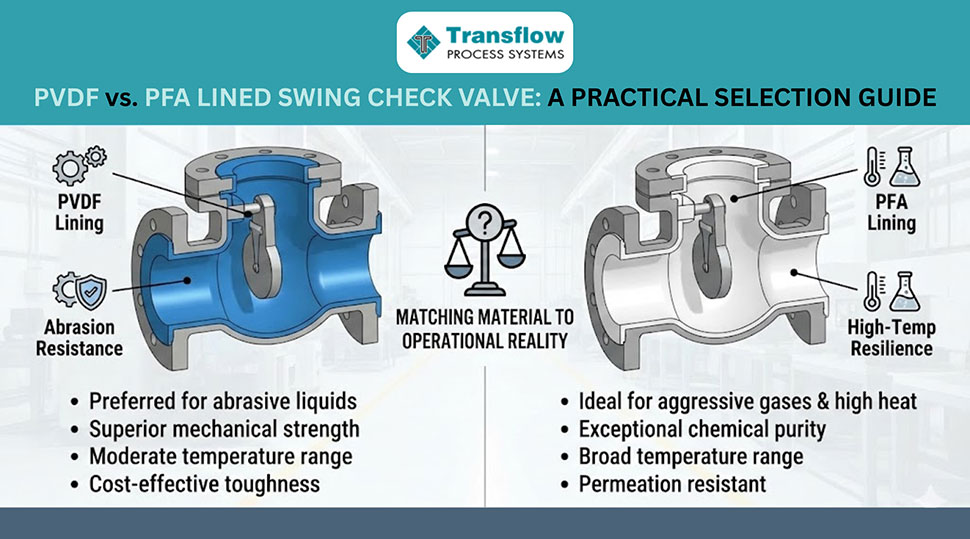

PVDF vs PFA Lined Swing Check Valve:Practical Selection Guide

In chemical industries, check valves often go unnoticed. Until they fail.

When that happens, it’s rarely just a minor maintenance ticket. It usually means

a pump spinning backward, product getting contaminated or a leak halting an

industrial pipeline.

It is the material that is the culprit. Conventional materials such as GI

(Galvanized Iron), PVC or concrete did

not work to be compatible with the Indian conditions- the ability to shift on

the red soil of Gujarat to the

extreme changes in temperature during our summers

The difference between a standard day and a costly shutdown often comes down to

one specific engineering choice , how you select the right lined valve.

This isn’t about definitions. It’s about matching material properties to

operational reality an approach you’ll see reflected in Transflow's company

profile.

The Invisible Guardian of Your Pipeline

A lined swing check valve has one job , sit there and wait. But the moment flow

reverses, it has to seal. Instantly.

In aggressive environments, a standard metal valve would deteriorate rapidly.

That is why a specialized corrosion resistant valve is essential. Lined check

valve designs use a fluoropolymer barrier to isolate the process media from the

metal body.

But here is the catch.

Not all barriers work the same way. Pick the wrong one, and you risk permeation

gas migrating through the plastic or the liner collapsing when the line goes

into vacuum.

Figuring out which material fits requires looking past the spec sheet.

Material Profile: PFA (Perfluoroalkoxy)

The High-Temperature Specialist

The PFA Lined Swing Check Valve is the standard for thermal extremes. PFA shares

the chemical inertness of PTFE, but because it is melt-processable, the shield

it creates is denser. Less porous.

- Primary Advantage : It’s often the choice for small-molecule gases media like Chlorine or HCl vapor. The density helps stop gas from permeating the liner to attack the metal body.

- Operational Consideration : If you are running hot, PFA is typically selected for its stability. It holds its structural integrity at temperatures where other plastics might start to soften.

Material Profile: PVDF (Polyvinylidene Fluoride)

The Mechanical Specialist

The PVDF Lined Swing Check Valve isn't just a cost-effective option , it is

frequently used for its physical toughness.

- Primary Advantage : If you have abrasive slurries or waste streams , PVDF is robust. It is tougher and more rigid than PFA , meaning particulates won’t wear it down as fast.

- Operational Consideration : You have to watch your chemistry. PVDF has known limitations with certain ketone-based solvents and high-pH caustics.

Decision Framework: Evaluation Criteria

To clear up the selection process, chemical processing applications usually get

assessed against three main criteria:

1. Operating Temperature Considerations

- High Temperature: PFA is generally favored to keep thermal deformation risks low.

- Moderate Temperature: A PVDF Lined Swing Check Valve often works well here. It brings extra durability against physical impact.

2. Media Characteristics (Gas vs. Liquid)

- Permeating Media: For gases, vapors, or penetrating liquids, PFA is often the top candidate. It resists permeation better.

- Standard Media: For standard liquids or slurries, PVDF is widely used.

3. Solids and Abrasion(h3)

- Abrasive Conditions: PVDF is commonly specified for its abrasion resistance.

- Clean Fluids: PFA is suitable, provided you’ve verified the chemical compatibility.

For deeper insights into fluoropolymer properties, refer to our Technology

page.

The Zero Leakage Reality

The term Zero Leakage is a technical requirement for tight shut-off under

defined conditions. In any lined check valve, shut-off performance depends

heavily on the liner staying dimensionally stable.

If you put a PVDF valve in a high-heat application, the liner might warp from

the thermal cycling. Once it deforms , the disc can't seat properly.

Reliable shut-off depends on respecting the temperature limits. That is why

quality testing protocols like those in Transflow’s quality testing practices

are used to verify the valve actually performs within its rating.

Final Summary: Engineering the Right Fit

There is no best material. There is only the correct material for the pressure,

temperature, and chemistry you are dealing with. When specifying a swing check

valve for acid service, precision is key.

- PFA : is typically prioritized for purity, heat, and aggressive gases.

- PVDF: is often prioritized for mechanical toughness and abrasive liquids.

Whether you are specifying a Lined Jacketed Ball Valve or a specialized check valve, precision matters.